PEGylated Particles

Properties

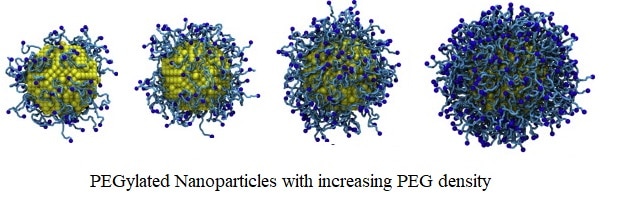

Creative PEGWorks offers PEGylated particles or beads including silica, agarose (crosslinked), gold nanoparticles, silver nanoparticles, quantum dots, TiN (titanium nitride) nanoparticles, carbon nanotubes, graphene, magnetic particles, latex beads, europium nanoparticles, glass slides, liposome, polystyrene beads among others. We have a streamlined process to conjugate PEGs of various MW or length to the surface of beads. The PEG density on particle surface can be controlled per clients requests.

PEG molecular weight options include all PEG types we offer. Typically the PEG MW may be 550, 1k, 2k, 3.4k, 5k, 10k, 20k, and 30k. The standard PEG is a linear methoxy-capped PEG (aka mPEG).

The number of PEG for each particle depends primarily on your application and is limited by the number of reactive groups on the particle surface and also by the size of PEG and curvature of the particle. We have developed proprietary chemistry protocols to precisely control the number of PEG per particles. The typical PEG coating density is 0.1 to 2.0 PEG chains/nm². Factors Influencing Density: 1) PEG molecular weight: Lower MW (e.g., 2–5 kDa) supports higher densities; higher MW (e.g., 10–20 kDa) limits density due to steric hindrance. 2) Particle curvature and size: Smaller particles (< 50 nm) accommodate higher densities due to increased surface area-to-volume ratio. The PEG coating can be calculated by thermogravimetric analysis (TGA).

The physical form of the final product may be lyophilized powder, solid, or suspension in a specified buffer solution.

Get In Touch

If you have any questions, please submit an online inquiry.

"*" indicates required fields