PEGs by Industry & Application

Industry:

Pharmaceutical

In the pharmaceutical industry, PEG products are used in drug delivery systems to improve the pharmacokinetics and pharmacodynamics of drugs. PEGylation of drugs increases their solubility, stability, and half-life, allowing for targeted drug delivery and reducing side effects. PEG products can also be used as excipients in drug formulations, providing a suitable environment for drug molecules and improving their efficacy.

Industry:

Medical R&D

In the medical field, PEGs are found in biomedical research and biotech R&D. They can be used for dye-labeling biological molecules which is useful in such instances of cancer research or gene therapy. PEGs can also be modified and crosslinked into a hydrogel then utilized as an extracellular matrix for cell encapsulation and medical study. PEG hydrogels are a vital environment for proper medical R&D and are often found in medical university laboratories and cancer research facilities. They act as models for sustained biological research and experimentation.

Industry:

Commercial

From synthetic fibers in clothes to hygiene products PEG use can be found across a variety of commercial industries. PEGs are used in hair care, skincare, and personal care products. PEGs are used as emollients, humectants, and thickeners, providing a smooth and moisturized feel to the skin and hair. PEGs are also used as solubilizers, allowing for the incorporation of oil-based ingredients into water-based formulations. Foam cushions and polyester fibers are made up of polymer segments derived from PEG polyols.

Industry:

Industrial

In industrial applications, PEG products are used as lubricants, propellants, surfactants, and dispersants for surfaces in both aqueous and non-aqueous environments. PEGs are often used in the production of adhesives, paints, and coatings, where they improve the properties of the final product, such as viscosity, stability, and durability.

PEGs by Application

PEGs are utilized in many industries spanning from medical to industrial fields. The application of PEGs are found in pharmaceutical research, nanotechnology, drug development, biotech R&D, hydrogels, chemical experimentation, crosslinking, and other applications. At Creative PEGWorks, we know PEGs are the building blocks of innovation – and we exist to supply you with the most reliable high-purity PEG derivatives.

PEGylation

The application of PEGylation involves modifying the drug or protein with PEG chains of varying lengths and structures, depending on the desired properties. PEGylation can improve the solubility, stability, and half-life of the therapeutic molecule, making it more effective for therapeutic use.

One of the primary applications of PEGylation is in the development of long-acting drug formulations. PEGylation can extend the half-life of a drug, allowing it to remain in the body for a longer period, resulting in a reduction in the frequency of administration. This can improve patient compliance and reduce the overall treatment cost.

Another important application of PEGylation is in the development of protein-based therapeutics. Proteins can be modified with PEG chains to increase their stability and solubility, protecting them from degradation and enhancing their therapeutic efficacy. PEGylation can also reduce the immune system’s recognition of the protein, reducing the likelihood of an immune response, which can be a significant challenge in protein-based therapeutics.

PEGylation is also used in the development of diagnostic agents, such as contrast agents for imaging. PEGylation can increase the circulation time of these agents, allowing for more precise and accurate imaging.

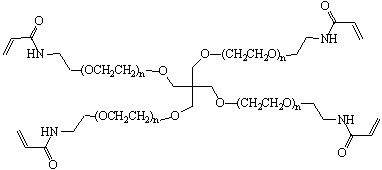

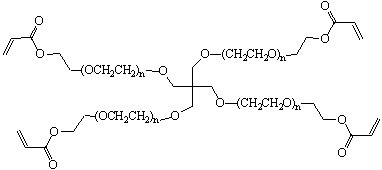

Hydrogels

Hydrogels are three-dimensional, cross-linked polymer networks that can absorb and retain large amounts of water. They are used in a wide range of applications due to their unique properties, such as high water content, biocompatibility, and tunable mechanical and chemical properties.

Crosslinking kits are commonly used in the creation of hydrogels, three-dimensional polymer networks that can absorb and retain large amounts of water, which have numerous applications in drug delivery, tissue engineering, and wound healing.

Hydrogels are used in various applications, including drug delivery, tissue engineering, and wound healing. Hydrogels can be designed to mimic the extracellular matrix, providing an ideal environment for cells to grow and develop. They can be used to deliver drugs or proteins to specific sites in the body, allowing for targeted therapy with reduced side effects. Hydrogels are also used in wound healing, as they can provide a moist environment for the wound to heal, preventing scarring and promoting tissue regeneration.

Lipid Nanoparticles

Lipid nanoparticles (LNPs) are nanoparticles composed of lipids. They are a novel pharmaceutical drug delivery system, and a novel pharmaceutical formulation. LNPs as a drug delivery vehicle were first approved in 2018 for the siRNA drug. LNPs became more widely known in late 2020, as some COVID-19 vaccines that use RNA vaccine technology coat the fragile mRNA strands with PEGylated lipid nanoparticles as their delivery vehicle. LNPs used in mRNA vaccines for SARS-CoV-2 (the virus that causes COVID-19) are made of four types of lipids: an ionizable cationic lipid (whose positive charge binds to negatively charged mRNA), a PEGylated lipid (for stability), a phospholipid (for structure), and cholesterol (for structure). Because of rapid clearance by the immune system of the positively charged lipid, neutral ionizable amino lipids were developed. A novel squaramide lipid (that is, partially aromatic four-membered rings, which can participate in pi–pi interactions) has been a favored part of the delivery system used.

PDC and ADC Linkers

Antibody-drug conjugate linkers, or ADC linkers, peptide-drug conjugate linkers or PDC linkers are a type of chemical linker used in the development of antibody drug conjugates (ADCs) or peptide-drug conjugates (PDCs). ADCs and PDCs are a type of targeted cancer therapy that uses monoclonal antibodies or peptides to deliver cytotoxic drugs directly to cancer cells, reducing the risk of systemic toxicity.

ADC linkers typically contain a PEG linker as part of their structure. A PEG linker is a short chain of polyethylene glycol (PEG) molecules that is used to attach two or more molecules together. PEG linkers are commonly used in the development of drug conjugates and in protein engineering to create fusion proteins or to attach tags for detection or purification.

The linker is a critical component of the ADC, as it connects the antibody and the drug payload. The linker must be stable in circulation to prevent premature release of the drug, but also be able to release the drug once inside the cancer cell.

ADC linkers are designed to be cleaved under specific conditions, such as low pH or the presence of certain enzymes, such as proteases. This enables the drug to be released in the targeted cancer cell, where the cleaving conditions are present.

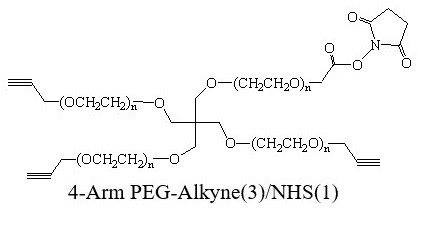

Click Chemistry

Click chemistry involves the use of highly reactive, small molecules that react with each other under mild reaction conditions, to form a stable product. The reaction is often described as “click” because of the ease and efficiency of the reaction.

One of the primary applications of click chemistry is in the synthesis of new drugs. The highly efficient and selective nature of the reaction makes it an ideal tool for synthesizing complex molecules with high yields. Click chemistry can also be used to modify existing drugs, improving their pharmacological properties or making them more selective.

In bioconjugation, click chemistry is used to link two molecules together, such as a protein and a small molecule. The highly selective nature of the reaction allows for the creation of precise and stable conjugates that can be used for a variety of applications, including targeted drug delivery and imaging.

One of the most commonly used click chemistry reactions involves the use of a DBCO reagent (dibenzocyclooctyne) and azide. This reagent contains a strained cyclooctyne ring that reacts with azide functional groups in a highly specific and efficient manner, forming a stable triazole linkage.

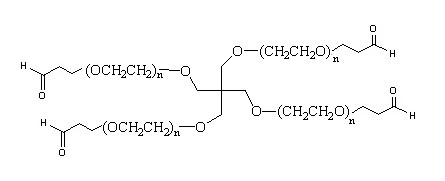

Dye Labeling

Dye labeling is a chemical process that involves attaching fluorescent dye or color dyes to biological molecules, such as proteins or nucleic acids. Fluorescent dyes are commonly used in dye labeling applications to visualize and track biomolecules and cells, allowing for a better understanding of biological processes.

In imaging applications, dye-labeled molecules can be used to visualize the localization and movement of specific molecules within cells or tissues. The fluorescent or color dyes emit light that can be detected using microscopy, allowing researchers to study the spatial distribution of molecules within biological samples.

In quantification applications, dye labeling can be used to measure the amount of a specific molecule present in a sample. The intensity of the dye fluorescence or color can be correlated with the amount of the labeled molecule, allowing for accurate and precise quantification.

In detection and sensing applications, dye-labeled molecules can be used to detect the presence of specific molecules or biomarkers. For example, dye-labeled antibodies can be used to detect the presence of specific proteins in biological samples, allowing for the diagnosis of diseases or the monitoring of disease progression.

Drug Delivery

Drug delivery systems have the potential to improve the efficacy and safety of drugs by targeted delivery to specific tissues or organs, to minimize off-target and off-tissue toxicities.

One such technology is controlled drug release systems, which can release drugs in a controlled and sustained manner over an extended period. These systems can be designed to release the drug at a specific rate, location, or trigger, ensuring that the drug reaches the target site in the desired concentration and for the desired duration.

Another drug delivery technology is targeted drug delivery, which involves delivering the drug specifically to the diseased tissue or organ. This technology reduces the exposure of healthy tissues to the drug, minimizing side effects, and improving the efficacy of the drug. Targeted drug delivery can be achieved using various methods, such as antibody-drug conjugates (ADCs), liposomes, and nanoparticles.

Featured PEGs

PEG Product Use Case

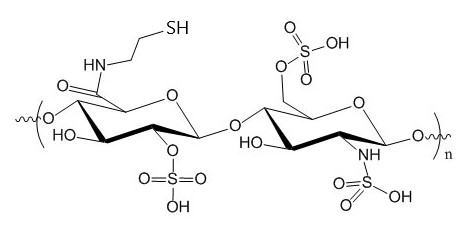

Polysaccharides

In the pharmaceutical industry, polysaccharides are used for drug delivery, wound healing, and tissue engineering. Polysaccharides have excellent biocompatibility and biodegradability, making them an ideal material for biomedical applications.

In industrial applications, polysaccharides are used as gelling agents, binders, and lubricants. They are also used in the production of paper, textiles, and adhesives, where they improve the properties of the final product, such as strength, stability, and durability.

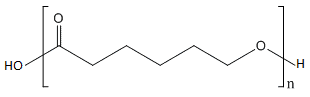

PEG Copolymers

PEG copolymers are block copolymers composed of polyethylene glycol (PEG) and a monomer such as polylactide (PLA) or polyglycolide (PGA). These copolymers combine the unique properties of PEG, such as biocompatibility and water solubility, with the properties of the other monomer.

In drug delivery applications, PEG copolymers are used to improve the pharmacokinetics and pharmacodynamics of drugs. The copolymers can be designed to release drugs in a controlled and sustained manner, improving drug efficacy and reducing side effects. PEG copolymers can also be used to target specific tissues or organs, improving drug delivery to the desired site.

In tissue engineering applications, PEG copolymers can be used as scaffolds for tissue regeneration. The copolymers can be designed to mimic the extracellular matrix, providing an ideal environment for cell growth and development. The copolymers can also be modified to incorporate bioactive molecules, such as growth factors, promoting tissue regeneration and repair.

In medical device applications, PEG copolymers can be used as coatings to improve biocompatibility and reduce immune response. The copolymers can also be used to modify the surface properties of medical devices, such as stents or catheters, improving their performance and reducing complications.

PEG Beads / Biobeads

PEG beads, also known as biobeads, are highly versatile and valuable materials used in various applications, including chromatography, protein purification, and drug delivery. These beads are composed of crosslinked polyethylene glycol (PEG) and can be modified with various functionalities, making them an ideal material for many applications.

In chromatography applications, PEG beads are used as a stationary phase to separate and purify biomolecules, such as proteins and nucleic acids. The high surface area and high binding capacity of PEG beads make them an ideal material for chromatography, allowing for efficient and effective biomolecule separation and purification.

In cell culture and tissue engineering applications, PEG beads can be used as scaffolds for cell growth and development. The highly porous structure of PEG beads provides an ideal environment for cell attachment and growth, promoting tissue regeneration and repair.

PEG beads can also be used in drug delivery applications. The highly functional surface of PEG beads allows for the attachment of various drug molecules, improving drug efficacy and reducing side effects.

Surface modification of PEG beads can improve their performance and functionality in various applications, such as drug delivery and protein purification.

PEGylation Reagents

PEGylation reagents are highly valuable materials used in the process of modifying biomolecules, such as proteins or peptides, with polyethylene glycol (PEG) molecules. This process is known as PEGylation, and it has numerous applications in the pharmaceutical and biotechnology industries.

In the pharmaceutical industry, PEGylation reagents are used to modify drugs, improving their solubility, stability, and half-life, and reducing immunogenicity and toxicity. PEGylated drugs have several advantages, such as improved efficacy, reduced dosing frequency, and fewer side effects, making them an attractive option for drug development.

In protein therapeutics, PEGylation reagents are used to modify proteins, such as enzymes or antibodies, improving their pharmacokinetics and pharmacodynamics. PEGylation increases the protein’s stability and half-life, reducing the need for frequent dosing and improving patient compliance.

In diagnostic imaging, PEGylation reagents are used to modify contrast agents, improving their solubility and biodistribution. PEGylated contrast agents have improved pharmacokinetics, allowing for enhanced imaging and diagnosis of diseases.

Our team of experts is dedicated to providing customized solutions to meet our customers’ specific needs and requirements, ensuring that our PEGylation reagents meet the highest standards of quality and performance.

Polyesters

Polyesters are a class of polymers that are composed of ester monomers. They are versatile materials used in various applications, including textiles, packaging, and biomedical applications.

In biomedical applications, polyesters are used to produce various medical devices, such as sutures and drug delivery systems. Biodegradable polyesters, such as polylactide (PLA) and polyglycolide (PGA), are used in tissue engineering and wound healing applications. These materials are biocompatible and biodegradable, allowing for safe and effective use in the human body.

Whether you need polyester for textile production, packaging, or biomedical applications, Creative PEGWorks has the expertise and experience to provide you with the right solution.